|

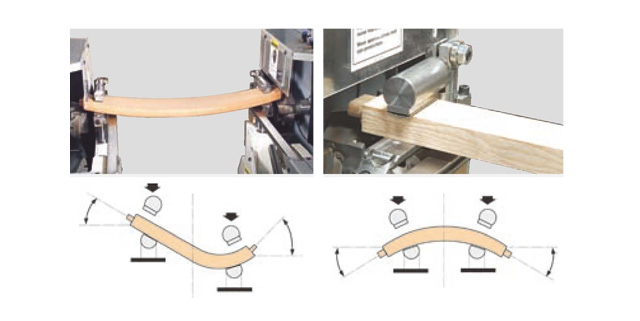

Warpped Workpiece Tenoning

|

|

YOW CHERNG YRT-D100 / D200 A Profitable Peformer ! |

|

Outstanding Features: 1. Equipped with a PLC control combined with touch sensing screen for user friendly operation. 2. Fully automatic tenoning operation greatly upgrades production output. 3. Cutting tenons at both ends simultaneously for greatly increasing efficiency and productivity. 4. Designed for producing rectangular and cylindrical tenons. 5. The machine is suitable for producing horizontal, vertical and mitered tenons. 6. Cutter feed speed is controlled by frequency inverter, allowing for variable speed change. 7. Equipped with an workpiece magazine for fully automatic operation. 8. workpiece feed slideways are equipped with precision linear motion guides,ensuring fast and stable feed motions.

|

Convenient Tenon Width Adjustment

Tenon width adjustment is conveniently made by simply turning the adjustment knob.

A mechanical meter is equipped for accurately indicating the width adjustment amount.

Workpiece Magazine

The finished products will automatically outfeed to the product rest, permitting operators to take products with ease.

User-Friendly Control

The machine is equipped with a PLC for controlling the entire motion sequences. It combines with touch sensing screen, providing maximum operation convenience. An Amp.meter is provided on the control panel for indicating the loading condition on main motors. The controller provides major

functions as below:

Production quantity setting and display.

Smooth Feed Motion

Feed carriages at both sides are transmitted by a single shaft,ensuring synchronized travel

|

Model/ Kiểu máy |

YRT-D100 |

YRT-D200 |

|

Length of cut/ Chiều dài cắt |

180-1500 mm |

180-2000 mm |

|

Spindle speed/ Tốc độ trục chính |

9000 R.P.M. |

9000 R.P.M. |

|

Maximum tenon width/ Chiều rộng lớn nhất của mộng |

100+2R mm |

100+2R mm |

|

Maximum tenon depth/ Chiều sâu tối đa của mộng |

40 mm |

40 mm |

|

Minimum tenon depth/ Chiều sâu tối thiểu của mộng |

10 mm |

10 mm |

|

Maximum tenon thickness/ Chiều dày tối đa của mộng |

30 mm |

30 mm |

|

Cutter drive motor/ Động cơ lưỡi cắt |

3 Kw x 2 (4 HP x 2) |

3 Kw x 2 (4 HP x 2) |

|

Rotation motor/ Động cơ xoay vòng |

0.75 Kw x 2 (1 HP x 2) |

0.75 Kw x 2 (1 HP x 2) |

|

Head position adjustment motor/ Động cơ điều chỉnh vị trí đầu |

1 Kw (1.5 HP) |

1 Kw (1.5 HP) |

|

Total horsepower/ Tổng công suất |

8.6 kw (11.5 HP) |

8.6 kw (11.5 HP) |

|

Working air pressure / Áp xuất làm việc |

6 BAR |

6 BAR |

|

Dust hood outlet diameter/ Đường kính outlet |

Ø60 mm x 2 / Ø100 mm x 2 |

Ø60 mm x 2 / Ø100 mm x 2 |

|

Gross weight/ Trọng lượng |

2915 kg |

3155 kg |

|

Machine dimensions/ Kích thước máy |

3350 x 2000 x 1900 mm |

3850 x 2000 x 1900 mm |

|

Packing dimensions / Kích thước làm việc |

3470 x 2000 x 2000 mm |

4000 x 2000 x 2000 mm |

Công ty chúng tôi rất hân hạnh phục vụ quý khách hàng

Công ty TNHH đầu tư quốc tế Việt Nam

Địa chỉ: Số 2010, tòa nhà CT3A, khu đô thị Văn Quán, Hà Đông, Hà Nội

Điện thoại: 0912 817 066- 0912 666 817

Website: maylaserhn.com- maycnc.com

Hotline

024 35 666 727

Hotline

0963 060 905 - 0934 682 818

11-06-2015|135194

Chắc hẳn các bạn đã làm quen với lập trình máy CNC thì sẽ thấy những điều này thật quen thuộc nhưng với những bạn mới bước vào CNC, chắc chắn điều...